FIBERFLON® is also the name of leadership in manufacturing of high performance process belts. FIBERFLON® industrial conveyor belts combine the non-stick surface and heat resistance of PTFE (polytetrafluoroethylene) and with the strength and dimensional stability of fiberglass. The unique behaviour of these materials results in a product that is more practical and cost-effective than conventional belting materials which is ideal for the demands of many different industrial conveyor applications. Dimensionally stable from -73° to +260°C (-100° to +550°F), FIBERFLON® belts are non-toxic, tasteless odorless, EU food regulations and FDA compliant (21 CFR 177.1550) for use in food contact processing and packaging. In addition, FIBERFLON PTFE belts offer exceptional durability and extremely low elongation (<1%).

BELT JOINT (SEAM) TYPES

Alligator

|

Metal Clipper

|

PEEK-Spiral

|

Bullnose

|

Castellated

|

Overlap |

EDGE REINFORCEMENT TYPES

PTFE film

Edge Reinforcement

|

PTFE / glass

Edge Reinforcement

|

PTFE-Kevlar

Edge Reinforcement |

BELT TRACKING / GUIDING TYPES

A guiding system is essential for most of PTFE belts. Guiding may be

by external guiding systems or by combining a system in the belt

construction, such as metal studs, teflon pins or eyelets. External, electrical

or mechanical systems are preferred, since they are suitable for all

widths of belts and prolong belt life by preventing edge damage due to

incorrect tracking.

Tips for optimizing belt life; Run at low tensions, use only flat

rollers, ensure each roller is aligned properly and utilize an automatic

guiding system.

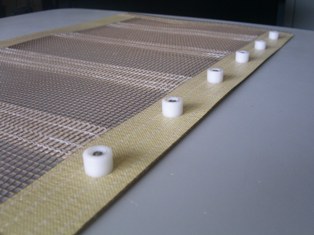

Stud Guides

The belts run with tracking studs inserted in to one edge of the belt that then locate in to a machined groove in the rollers of the conveyor. This prevents the belts from tracking off and extends the belts life.

Kevlar Guides

Kevlar Guides

The belts run with tracking kevlar guides inserted in to one edge of the belt that then locate in to a machined groove in the rollers of the conveyor. This prevents the belts from tracking off and extends the belts life.

PTFE Pin Guides

PTFE Pin Guides

16 mm Ø x 12 mm H Teflon Pin Guides are available on one side of any type belt. Kevlar edge reinforcement is recommended for strong connection pin guide to the belt. This type of pin guide is resistant up to 260°C temperature.

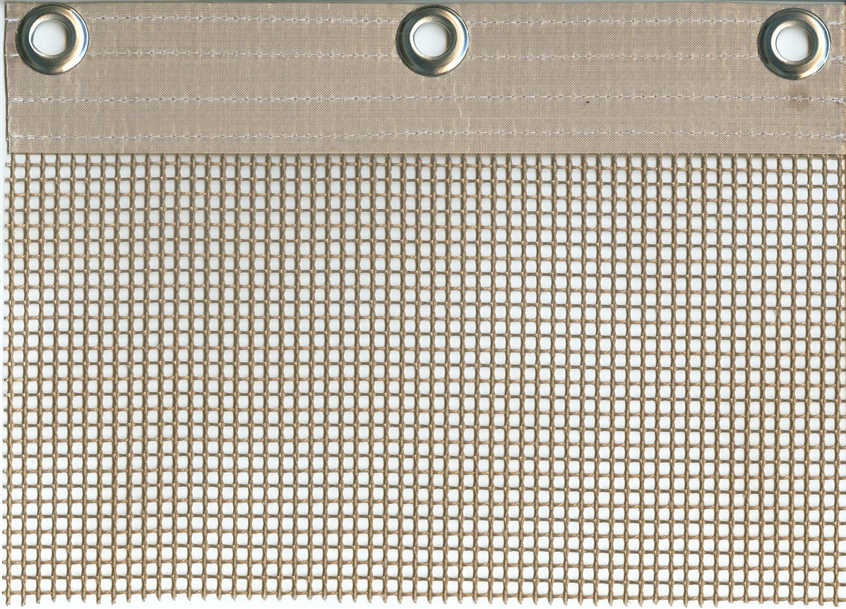

Metal Eyelets

We can make different diameter eyelets to both sides of any type belt. It is possible to connect eyelets with springs for belt tracking. Please consult your sales person if different size of diameters are requested.

Fiberflon® belts are delivered ready for installation with seam and edge

reinforcement. Several type of seams, joints, splice and edge

reinforcements are available according to process type.

We serve following industries and others;

Contact grill belts, food processing belts , Tortilla press belts, Textile dryer belts, printing dryer belts,

Garment fusing press belts, Packaging machinery, plastic bag sealing,

side sealing, over wrapping, tray wrapping and end sealing machine

belts, Shrink packaging tunnel belts, Screen print dryers, Rotary band

sealers, Rubber profile extrusion belts, PVC and Rubber backed carpet

belts, lamination belts, Solar panel and photovoltaic lamination belts,

Belt Joint / Seam / Splice Types

Edging / Guiding Information